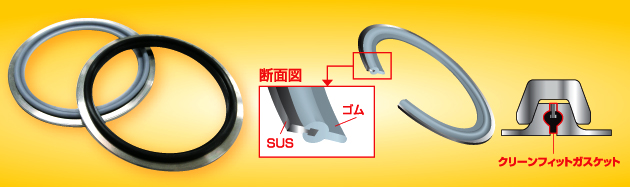

Clean Fit Gasket 【Type GSC-C】

■Features ・An original design dimension having an SUS manufactured ring on the outer periphery. ・The gasket does not protrude inside the piping. ・Can be attached to an ISO Standard ferrule. ・The material has cleared the requirements for the Food Sanitation Act. ※Since rubber is selected capable of clearing all items of the evaporation residues test under the harsh conditions of use at temperature condition of 100 degrees Celsius or more, this is capable of being used with ease. 【The merits of having the SUS manufactured ring】 ・By having the SUS manufactured ring, excessive tightening is suppressed and the tightened amount is capable of being made constant. ・No rubber protrusion occurs since the tightened amount is capable of being made constant. (Inside diameter is also of a dimension taking the heat effect into consideration so that the rubber does not protrude under suitable environment of use.) ・Rubber abnormal deterioration is not accelerated since excessive tightening is capable of being suppressed. ・Sealing property is improved since radial run out of the shaft is alleviated. ・Intrusion of liquid to a gasket surface is capable of being prevented since sure sealing can be carried out. 【It is effective in such circumstances】 ・The service life seems short compared to sealing in periphery instruments. ・There is insecurity in sanitary properties with the gasket protruding inside. ・Wish to carry out pig cleaning but there is a risk of damaging the gasket and making it foreign matter. ・Wish to carry out torque management for the clamp handle. Etc.

※Please appoint materials on the occasion od an order. 【Caution】Although the gasket unit is recessed at attachment to prevent gasket from protruding inside, it is designed so that the recess is made minimum. Securing sufficient sanitary properties was confirmed in a washing test.

The inside diameters of 1.0s and 1.5sare different. |